Our timeline

In 1869, the young, 25-year-old entrepreneur Rasmus Færch founds R. Færch’s Cigar- og Tobaksfabrikker A/S in his hometown of Holstebro in western Jutland in modest premises near the town centre. Subsequently, many generations of the Færch family are involved in the rapidly growing company, and in 1961 Rasmus Færch decides to merge with the tobacco companies Chr. Augustinus and C.W Obel to form Skandinavisk Tobakskompagni - Scandinavian Tobacco Company. Today, the company is one of Europe’s leading tobacco companies.

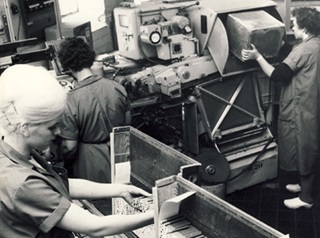

The picture shows all the “strippers”. This was the name given to the ladies whose job was to strip the tobacco by removing the stems and ribs from the tobacco leaves so they could be used to roll cigars. The fine, smooth leaves were used for wrappers, i.e. the outer layer, while the more creased leaves were used for the filling.

In 1969, the Færch family withdraws from the tobacco industry, but Jørgen Færch, the visionary and energetic chairman of the Board of Directors, is far from finished with running a business. That same year he purchases four machines for producing plastic packaging from a disused factory on Zealand, moves them to Holstebro and starts Færch Plast.

Jørgen Færch can use his previous experience and reemploys key employees from the tobacco facotory. The foundations are thereby laid for what is today Europe’s leading manufacturer of packaging for the food industry.

From the outset, Jørgen Færch has bold ambitions for the plastics company, and bold ambitions demand space. He therefore purchases the 38,000 sqm plot on Rasmus Færchs Vej 1 in Holstebro, the site of the present factory, and in 1973 he builds modern and up-to-date production facilities that match both his production goals and ambitions.

Færch Plast quickly establishes itself as a key player in the Danish market, and the rapid development in Denmark immediately enables Jørgen Færch to look at the possibility of further development opportunities. He starts collaborating with the UK sales agency George Harrison Ltd, and the UK thus becomes Færch Plast’s first export market. Today, the UK and Ireland are still the company’s biggest export markets.

The picture shows Jørgen Færch receiving the “HKH prins Henriks æresmedalje”, which was awarded in light of the special business relations between Færch Plast and the United Kingdom. The third person in the photography is Joe Iannidinardo, former Managing Director of Faerch Plast Ltd.

In 1987, Jørgen Færch retires at the age of 62. In the following years, the company he started is successfully for both the Færch family and for the local community, as the business expands from having a workforce of 110 to employing 400 people in 2001 and with revenues in excess of DKK 500 million.

The development is largely down to the acquisition of modern extruders, the opening of a sales office in France and the setting up of the Nordic region.

Back in the old days, employees grilled sausages over the nozzles and the smoke in the production hall.

That stopped however, and in 1998 Færch Plast becomes one of the first companies in Denmark to be certified according to ADAS, a rigorous UK hygiene certification.

Cleanliness and orderliness have subsequently characterised operations at Faerch, and the company has since been certified according to current ISO standards and Crc/IoP.

During the 1990s, Færch Plast starts focusing on the company’s energy consumption and environmental impact. By means of targeted investments and employing someone responsible for energy consumption, the company successfully reduces its energy consumption by a third for each tonne produced.

A groundwater cooling plant, dispensing with pre-drying and having a heat pump installed contribute to Færch Plast becoming a pioneering company in terms of energy within its line of business. picture shows the groundwater cooling system, which on its own reduces energy consumption by an amount corresponding to the energy consumed by 600 households a year.

Ten years after welcoming in the new millennium, the company is characterised by organic growth and expansion.

Thanks to Færch Plast’s strong market position and considerable business potential, a major expansion project of both the factory and the machinery is carried out in Holstebro, taking the total covered area up to 46,000 sqm.

To get close to the Central and Southern European markets, in 2008 Færch Plast builds a new and modern factory in Liberec in the Czech Republic with 80 employees, which expands the company’s production capacity by 10%.

Faerch Plast opened a new, 14,000 sqm production facility in the English north-eastern town of Durham.

A significant share of production for the UK market was transferred to the new factory as part of the strategy to reduce costs, improve efficiency, and reduce environmental impact. The new factory supports and improves service to Faerch Plast’s customers.

The same year, to provide a stronger market position in Southern Europe, Faerch Plast sales office in France was relocated to Semoy just outside of Paris.

The Board of Directors of Faerch Holding entered an agreement with the private equity fund EQT to buy Færch Plast A/S.

Morten Hummelmose, partner in EQT, had the following comment on the acquisition:

“EQT has followed Faerch Plast through a number of years and we are deeply impressed by the quality and the commitment of the employees we have met during the process. Faerch Plast has very significant market positions with longstanding, string customer relationships. These factors all constitute a sound basis for continuing the company’s outstanding development.”

In 2015, Færch Plast acquired Anson Packaging Ltd in England and Sealed Air’s Food tray business in Europe, with factories in England and Spain. The two acquisitions make Færch Plast a strong, international player with more than 1,100 employees distributed across its production facilities in Denmark, England, the Czech Republic and Spain, in addition to sales offices covering all of Europe.

Lars Gade, President and CEO of Færch Plast, says about the two acquisitions:

“They give us a wide-ranging and stronger product range. This means that we can now offer far better customer coverage throughout Europe.”

Færch Plast Group A/S is sold to Advent International – one of the world’s largest and most experienced equity funds.

Benjamin Buerstedde, Director at Advent International, states:

”Faerch Plast’s outstanding reputation in the marketplace, its dedicated management and its strong operational set-up make this an exciting investment opportunity. We look forward to working with the management team to further grow the business.”

Just eight months after private equity fund Advent International acquired Faerch Plast, Faerch reaches a new milestone with the acquisition of CGL Pack with two manufacturing sites in France.

Faerch Plast Group CEO, Lars Gade Hansen, states:

“We are impressed by the extensive product portfolio at CGL Pack and their innovative design capabilities. Faerch Plast has a long history in the French market, and we believe the combination with CGL Pack would be an excellent opportunity for both parties, providing a much stronger foundation to deliver a broad, high quality product range to our customers.”

Faerch is closing the loop on plastic food trays with the acquisition of Dutch 4PET Group, a leading sheet manufacturer with unique recycling capabilities. With this acquisition, Faerch is becoming one of the world’s first integrated plastic packaging suppliers that achieves a circular economy for recycling food trays on an industrial scale, turning plastic packaging into a resource.

“For years, Faerch has been promoting sustainability, and all of our products are designed for recyclability. The acquisition of 4PET Group is an outstanding opportunity for us to close the loop and a leapfrog in terms of sustainability. With the modern infrastructure in place at 4PET to sort and process disposed plastic trays, we are able to transform used trays into raw material for new food contact products”, says Faerch Group’s CEO, Lars Gade Hansen.

Faerch acquires Sirap food packaging business in Italy, Poland and Spain from Italmobiliare in line with management’s strategic roadmap.

The Sirap acquisition comprises three production sites in Italy, one in Poland, one in Spain and close to 1,000 employees. “We warmly welcome our new colleagues joining the Faerch Group”, Lars Gade Hansen says. “We have always been impressed by Sirap’s rigorous customer orientation, the portfolio of innovative products, the highly skilled employees and their outstanding dedication to quality. Major investments are planned to make Faerch’s circular products like our patented MAPET®II for the Protein sector, CPET for hot-use applications or our unique Evolve by Faerch concept available. Food-to-Go customers across Europe will benefit from Sirap’s differentiating offerings providing excellent product presentation and anti-tamper closure systems”, he concludes.

Faerch becomes part of the A.P. Moller Group.

Lars Gade Hansen, CEO, Faerch Group: “We are delighted and proud to become part of the A.P. Moller Group. There is a perfect fit in terms of our core values, and we experience full support for our strategy to drive the industry’s transition towards circularity. Being part of the A.P. Moller Group with its outstanding family heritage, its long-term investment perspective and international network brings about many advantages and opportunities for Faerch.”

Jan Nielsen, CIO, A.P. Moller Holding: “As the investment arm of the A.P. Moller Foundation, we invest in and build businesses that have a positive impact on society – ‘nyttig virksomhed’. With its focus on making food packaging circular, Faerch certainly have a positive impact on society, and we are proud to welcome Faerch to the A.P. Moller Group. With our global presence and extensive network, we believe we will be a value-added and long-term partner assisting Faerch in accelerating its position as a leading sustainable food packaging company.”

Faerch will continue to operate as a separate company. With its new owners, Faerch will increase momentum further in leading the transition of food packaging towards circularity and scaling its successful tray-to-tray recycling business into additional countries.

The new name reflects the company’s commitment to truly circular recycling in food packaging. With additional capacity ordered, CIRREC scales tray-to-tray recycling to countries across Europe and drives the development of establishing food grade tray-rPET regenerated from pots, tubs and trays as a new commodity in the market.

The new name CIRREC emphasises the company’s focus on ‘CIRcular RECycling’. In contrast to down-cycling, circular recycling brings products back into their original application without loss in quality and food safety. Functional properties like food grade quality, colour, impact strengths etc. are preserved or fully recovered in the process.

“In a truly circular economy, food packaging becomes food packaging again. Bottles are recycled back into bottles, food trays become food trays again. Clear remains clear, and mixed colours are used for non-clear applications like in Evolve by Faerch,” Lars Gade Hansen, CEO of Faerch Group, sets out the ambition stating. “Each application cleans up for itself and provides its own feedstock. The textile industry does not steal from packaging and tray manufactures stop stealing from the bottlers,” he says. “This is what we call true circularity. And this is what we believe the future of rigid food packaging will be,” he continues.

Faerch acquires PACCOR Packaging from private equity firm Lindsay Goldberg. The acquisition is yet another important step in the execution of Faerch’s long-term growth plan and in accelerating the industry’s transition towards circular packaging solutions.

The acquisition underlines Faerch’s overall strategy for creating circularity in food packaging and will accelerate the required material conversion towards sustainable packaging solutions in the European dairy sector, the largest segment in rigid food packaging.

Offering a wide range of innovative packaging solutions mainly for the food industry, PACCOR is a European leader in protective packaging for the dairy sector. It has built a long track record of innovation and premium service for the largest and most demanding dairy customers, delivering state-of-the-art solutions mostly in yoghurt, spreads and ice cream packaging.

“With PACCOR’s strong position in the dairy sector, our complementary geographical footprints and our shared ambition to make food packaging circular, PACCOR is the perfect match for Faerch”, Lars Gade Hansen, CEO of Faerch Group, says. “We have always respected PACCOR for their dedication to quality, innovation and customer service, and we are delighted to now join forces with the excellent PACCOR team”, he continues.

Faerch Group acquires MCP USA

The acquisition expands Faerch’s geographical footprint beyond Europe and establishes a presence in the important US market. It is part of Faerch’s long-term growth strategy and underpins the ambition to lead the transition of food packaging towards true circularity globally. The transaction marks the first acquisition under Faerch’s new ownership by A.P. Moller Holding.

“We warmly welcome MCP USA and our new colleagues to the Faerch Group”, Lars Gade Hansen, CEO of Faerch Group, says. “Our circular solutions will complement MCP USA’s product range, setting us jointly at the forefront of making food packaging circular also beyond Europe”, he continues. In a circular economy, food packaging is made from recycled content and recycled back into new food packaging in an endless number of cycles. “MCP USA will serve as a stepping stone for Faerch entering the important US market, which is estimated to account for USD 55 billion. Being local will allow us to support the retailers, brand owners and food manufactures in making the right material choice for true circularity in the US food packaging market”, Lars Gade Hansen adds.

Faerch inaugurates the second tray recycling line at Cirrec and we triple our recycling capacity to manage 60,000 tonnes of input - marking the beginning of our scaling journey within the recycling division.

“This is not just a day of celebration for Faerch Group; it is a symbol of our commitment to reshaping a broken system and moving our industry from linear to circular business practices,” said CEO Lars Gade Hansen. “This transformation calls for collaborative efforts, and the invitation to our stakeholders to join us today also stands as an invitation to shape the road forward together with us.”